Which is suitable for vacuum brazing, CU-ETP or CU-OF?

Selection and Recommendations

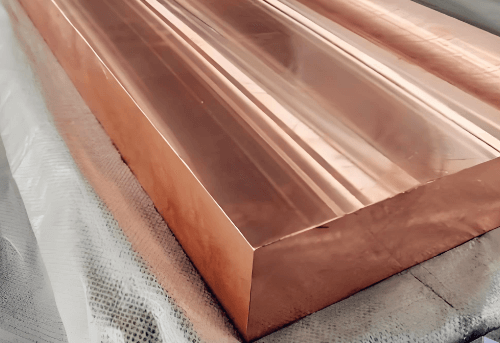

It is recommended to prioritize TU2 oxygen-free copper for vacuum brazing/vacuum diffusion bonding. With an oxygen content of ≤0.003% and

higher purity (Cu+Ag ≥ 99.95%), it offers advantages such as no hydrogen embrittlement, high electrical and thermal conductivity, and excellent

welding/brazing performance. This makes it particularly suitable for electric vacuum applications and high-reliability sealing connections.

In contrast, T2 represents ordinary copper (Cu ≥ 99.90%, oxygen≤ 0.06%) and is more prone to "hydrogen disease" and embrittlement

risks in vacuum/reducing atmospheres. This phenomenon is caused by the reaction between grain boundary Cu₂O and hydrogen, making T2 generally unsuitable as a

preferred base material for vacuum brazing.